Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Stamping technology is getting popular each day; it is the process of inserting flat sheet metal in either blank or coil form into a stamping press, where the metal is formed into the desired shape by a tool and die surface. Some of the most commonly used metals are steel, brass, and aluminum. The stamping process varies depending on what is being created, but most shapes are constructed of sheet metal that is placed on a stamping die and placed in a stamping press. In this article, I will tell you the top things you need to know about stamping technology.

The development history of stamping technology

The first metal stamping experiments were conducted on coins. The Lydian is said to have manufactured the first coins around the seventh century B.C., according to researchers. The Lydian made a die and cut the metal with a strong hammer to stamp the coins. Gold and silver were the most common metals used to make the coins. Metal stamping supplier, on the other hand, was not used in industry until the 1890s. Metal stamping was first used to fabricate bicycle parts by a German bicycle company. Metal stamping quickly gained popularity and efficiency as manufacturers discovered that technique allowed for faster and less expensive fabrication. Metal stamping is now an important process that is used in industries like the electronic industry, medical industry, automobile industry, consumer electronics industry.

The applications of stamping technology

Steel can be pressed into goods that require endurance and resistance to the elements because of its strength. Stamping suppliers can be used on a variety of materials depending on their particular metalworking properties for a variety of purposes in a variety of industries. Metal stamping firms work in a variety of industries, including (but not limited to): automobiles, medical machinery, and aeronautical equipment. Moreover, because of the electrical qualities of the zinc and copper that make it up, it can be employed in electrical devices.

The precautions for stamping process design

There are a few things to keep in mind when it comes to stamping technology. Here is a list of some considerations you should keep in mind.

l Selection of materials

You should choose the best material for different applications based on thickness, strength, and elasticity needs.

l The stamping component arrangement

You should optimize the layout, rationalize the design, and strive towards waste-free or low-scrap arrangements.

l Stamping design

To reduce waste, product criteria should be as straightforward and symmetrical as possible.

l Part thickness for reinforcement

The thickness of the stamped material should fall between the fixed range to ensure the life of the mold and the quality of the product.

The development prospect of stamping technology

The future of the metal stamping die industry is to achieve long-term growth. Metal stamping dies have become an essential arena for promoting demand and increasing economic growth points in recent years, thanks to a strong market development momentum. The stamping die sector will focus on high-end products and essential components in the future.

Who provides the best stamping technology?

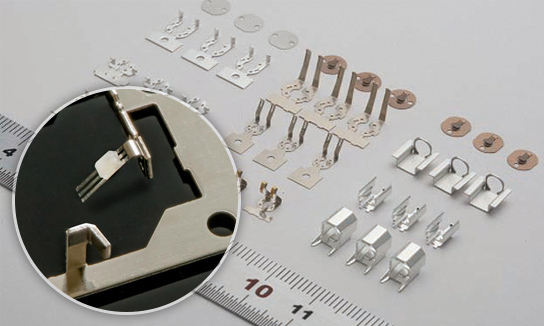

Finding the best stamping technology provider is not an easy job, but with the guidance of an expert, it becomes so simple and straightforward. As you come to the right spot, you don't need to research on your own. I have researched for you and have come up with the most reliable stamping technology, i.e., Hashimoto. For 19 years, we've specialized in metal stamping and tooling manufacture. The factory covers a total area of almost 3,000 square meters. To achieve high precision, domestic and international production and testing equipment is adopted. To promptly satisfy customer needs, the HSK group completes everything from die design to stamping mass production. We are certified to ISO9001, ISO14001, and IATF16949. Each item is thoroughly examined and tested. The percentage of eligible products is extremely high. We ensure that each customer's needs are met and that deliveries are made on schedule. We always control the quality and cycle of manufacturing efficiently.

Conclusion

Hashimoto handles everything from die design to stamping mass manufacturing, which is devoted to responding swiftly to customer demands. Hashimoto has been certified to ISO9001, ISO14001, and IATF16949. The raw materials are mostly non-ferrous metals with thicknesses ranging from T0.02 to T2.00mm. The goods are mostly utilized in consumer electronics, medical treatment, and automobiles for terminals, supports, shrapnel, magnetic shell, shielding cover, precise gasket, and other applications. You are welcome to contact us if you have any queries.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox